What to Expect During Professional Diamond Drilling Services

Drilling with a diamond bit is a dependable choice when accuracy, low vibration, and clean finishes are required. It’s especially useful for cutting through tough materials like concrete, stone, and reinforced surfaces. This method works well in commercial builds, industrial upgrades, and refurbishments. It also helps where noise and mess need to be minimal.

The benefit goes beyond just strong equipment. Diamond drilling done properly means fewer interruptions, more accurate cuts, and a safer environment. That kind of result takes more than just the right tool. It requires trained hands and a well-planned approach.

Core-ECT Diamond Drilling brings that expertise to every job in Mansfield. With years of experience and a professional team, we handle diamond drilling with precision, giving your project dependable results from start to finish.

Initial Consultation and Site Assessment

Every job starts with a conversation. We speak with you to understand what the project needs, where it’s located, and what materials are involved. This can happen in person or over the phone. It helps identify early if diamond drilling is the right fit and lays the foundation for a smooth operation.

Once we’ve reviewed the basics, we arrange a site assessment. Site checks are vital because every project space is different. A slab of concrete might be full of steel reinforcements. An older property could have hidden wiring or changes made over the years. By inspecting up close, it allows us to plan safely, choose equipment properly, and prepare for anything unusual.

At this stage, we look at:

1. The type of surface material and how thick it is

2. Where services like pipes or cables may be located

3. Local noise restrictions or dust control requirements

4. How accessible the area is for tools and workers

5. Where water, slurry, or power supplies can be managed

This part of the process cuts down delays on the actual drilling day. It ensures everything is ready, and nothing gets skipped.

Preparing the Drilling Site

With all plans in place, the drilling site gets prepared. A clean and organised workspace makes all the difference. We begin by removing any obstacles or loose materials that could get in the way. The area is cleared and floor protection may be added depending on the space and method used.

Next, we set up the drilling equipment. Depending on the project, the tool might be rig-mounted using bolts or clamps to keep it secure. This helps the bit stay steady and on target. Keeping the area tidy is just as important. Cables are tucked away to reduce trip hazards and warning signs are posted if it’s in a shared space.

On some projects, like those in residential flats, minimising disruption is important. Quiet equipment is selected when possible, and the team works around the building’s flow. Preparing well means we can get started quickly and without complaints from nearby occupants or workers.

Water supply is sorted beforehand too. It’s often used to cool the bit and control dust. We make sure it’s used safely, without creating pooling or slip risks. More time spent preparing means fewer mistakes during drilling.

The Drilling Process with a Diamond Bit

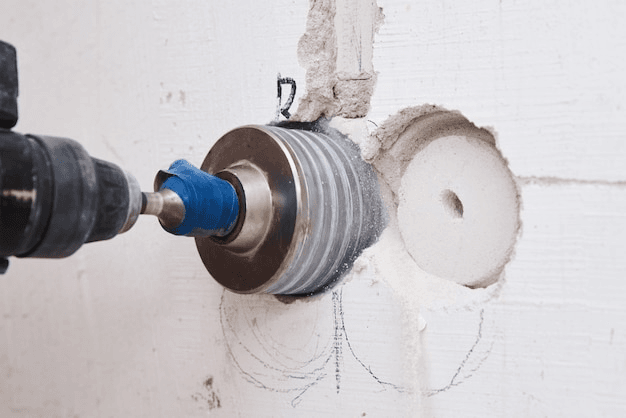

Once everything is stable and ready, we begin the drilling. The tool uses a rotating diamond-tip bit to cut through surfaces with care and speed. The bit spins fast but doesn’t shake the surroundings – which makes it great for precise work without cracking or breaking nearby sections.

We often use water cooling as we go. It keeps the temperature down, manages dust and slurry, and helps extend the lifespan of our equipment. It also helps keep your site cleaner. The choice of drill bit changes depending on what we’re drilling into. Stone, concrete, and asphalt all need different forces, speeds, and coolant levels.

Accessibility can make some drilling projects trickier. If there’s limited space to work in, we switch to handheld gear instead of rigs. It’s all about matching the right tools to the task.

Problems can come up, but our trained team knows how to handle surprises. If a bit hits rebar or if the rotation slows, we’ll change tactics without causing damage. Whether it’s switching bits, adjusting speed, or altering position, we stay on top of it to avoid delays and mess-ups.

Cleanup and Final Checks

Once the holes have been drilled to the right size and depth, we move into the final stage. Cleaning up isn’t just a courtesy. It ensures the area is safe, the job is tidy, and the drilled sections are ready to use.

Cleanup tasks include:

1. Removing all dust, water, and slurry

2. Dismantling and packing away equipment

3. Collecting waste for disposal away from your site

4. Checking surrounding surfaces for any residue or damage

5. Clearing pathways and removing trip hazards

After everything’s clean, we take measurements and conduct a visual check. Alignment, cut quality, and thickness are all confirmed before we officially finish the job. If the holes are for cables, anchor bolts, or plumbing, they need to match specification or they cause headaches later. We make sure that doesn’t happen.

Take a Mansfield school, for instance. If we’re booked over a weekend, everything, including the floors and ventilation, must be spotless before Monday. Our crews follow these expectations every time to avoid back-and-forth issues.

Why Precision Drilling Matters in Mansfield

Diamond drilling is about more than cutting holes. It’s about doing it safely, quietly, and correctly the first time. From the consultation to the cleanup, each part builds on the last to help your project move ahead without snags or hold-ups.

In a place like Mansfield, where schools, hospitals, residential renovations, or retail builds sit close to each other, things must be done neatly and with care. That’s the difference a well-planned service makes. Projects avoid unnecessary downtime. Buildings remain protected. And clients get what they need without surprises.

By following a trusted method and bringing the right skills and tools, Core-ECT Diamond Drilling delivers dependable results every time.

When your project calls for focused attention and a clean, efficient outcome, choosing drilling with a diamond bit is a reliable way to get results without the hassle. Core-ECT Diamond Drilling brings expert support to every site in Mansfield, helping you move forward with confidence and precision.