Addressing Water Leakage During Diamond Drilling Operations

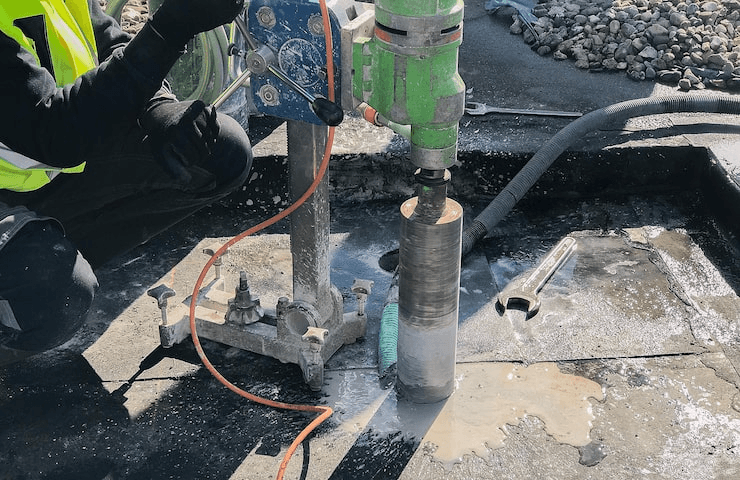

Water control is one of the most overlooked factors during diamond drilling jobs, but it can quickly become a serious issue if not handled properly. Water is used to cool the drill bit and flush away debris, but when it starts leaking or isn’t controlled, it can interfere with the entire operation. Drilling projects rely on accuracy and a clean workspace, and standing water or unexpected leaks can throw things off or stop progress altogether.

For jobs in Mansfield, where construction conditions can be variable depending on the site, managing water during drilling is especially important. Whether drilling through reinforced concrete or dense brickwork, addressing leakage early on helps keep things safe, clean, and efficient. Here’s a closer look at why this problem happens and what can be done to stop it from disrupting your project.

Common Causes of Water Leakage During Diamond Drilling

Water leakage during diamond drilling can happen for a few reasons, but most issues trace back to setup, equipment, or poor site conditions. Here are some examples of how and where leaks usually show up:

1. The wrong water flow rate: Too much water can overload the system and spill into unwanted areas, while too little causes overheating and pressurised backup, leading to overflow.

2. Faulty hoses or connectors: Cracks, worn fittings, or loose joins let water escape before it even gets to the drill point.

3. Poor sealing around the drilling area: Gaps between the drill guide and the surface allow water to run off away from the collection system.

4. No proper drainage: Without a clear way for water to exit, it builds up and seeps into nearby joints, indoors, or electrical areas.

5. Misaligned or unsteady equipment: If the drill rig isn’t level or securely fixed, guiding water correctly becomes harder, increasing the chance of leaks.

One example comes from a job in a tight indoor space where sealed concrete was being cored for plumbing runs. The drilling crew hadn’t spotted a backed-up drain from earlier work, so when water began flowing, it couldn’t escape. Within minutes, the water redirected through adjoining cracks in the floor and flooded a neighbouring room. This delayed the job and created extra clean-up that could have been avoided.

Dealing with these issues properly the first time helps prevent messy downtime and costly repairs. Knowing what to look for is the first step in keeping your site under control.

Impact of Water Leakage on Drilling Projects

The problems caused by water leaks can be more than just wet patches on the floor. They can lead to setbacks in the schedule, extra repair costs, safety risks, and in some cases, damage to other parts of the structure. Trying to complete a job while dealing with leaks puts extra stress on both workers and equipment.

Water in the wrong places can:

– Cause short circuits if it reaches nearby power tools or open outlets

– Lead to rot or damage in timber or drywall around drilling zones

– Weaken newly drilled surfaces where water has settled too long

– Slow down progress by making the drilling site hazardous or difficult to access

– Force rework if leaks carry cutting slurry to areas that need to stay clean

Water pooling around a drill site leads to slip risks, muddy conditions, and slurry that sticks to surrounding surfaces. It’s not just unpleasant—it makes the workplace less safe. Managing leaks before they spread helps avoid these problems and keeps drilling focused and productive.

Contractors across Mansfield work under tight timelines, and even a brief delay can push follow-on trades back or add extra costs from catch-up work. Accurate drilling with a diamond bit relies on clean conditions, which includes managing water from the start of the job.

Effective Strategies to Manage Water Leakage

Avoiding water leakage during diamond drilling starts with a proper setup tailored to the task and surroundings. A bit of planning goes a long way. Small oversights often become big setbacks. Keeping water handling in line from the first minute of work makes a big difference.

Here are some practical steps that help manage water during diamond drilling:

– Use the correct flow rate: Balance the water supply with the bit size and drilling speed. This keeps it cool without flooding.

– Inspect hoses and connectors: Replace worn or cracked parts before they become a problem mid-job.

– Seal the drilling point: Boot seals and rubber guards prevent water from escaping where it should stay in.

– Plan proper drainage: Give water a way out safely, whether using trays, slopes, or temporary channels.

– Use wet vacuum recovery systems: These collect water and slurry before they spread, ideal for indoor jobs or sensitive areas.

– Build simple barriers: Water dams made from mats or other materials protect floors near walls or adjoining rooms.

Taking these steps helps avoid delays and saves you from having to redo sections of work. In one Mansfield project, a contractor had to core into a ground slab within an occupied office. They used sealing mats, a changed spray pattern, and immediate vacuum recovery. That kept everything dry and neat with no flooding at all.

Good water control helps protect the hole quality, preserve the surroundings, and limit post-drilling tasks. With the right tools and habits, most problems are stop-before-they-start issues.

Core-ECT Diamond Drilling’s Approach to Managing Water Leakage

Managing water leakage is part of every setup we do. Every site is different, and each one calls for a plan that works for the conditions. What works on an outdoor slab may be wrong for a tile-lined corridor in a school. That’s where experience pays off.

Before any drilling begins, we assess key points like surface type, drainage options, floor slopes, and nearby finishes. That lets us match the method to the task. In some cases, we adjust flow through manual feeds. Other times, vacuum units or sealed systems are better. We adapt until everything stays where it should.

Throughout the job, we check the setup often. Connectors are tightened. Wet zones are managed. Nearby areas stay clean. And we don’t work in isolation. Talking with site managers helps us time and space our jobs to avoid disruption.

Working with a diamond bit means staying sharp in every respect—equipment, setup, and water. We treat water control with the care it deserves. Done right, the result is a clean, accurate hole and a job site that can keep moving.

How Mansfield Jobs Benefit from Good Water Control

Construction projects in Mansfield face mixed conditions. Soils vary. Building designs throw up unusual access points and finishes. Weather shifts quickly, and many sites are in close-quarters or mixed-use environments. That’s why solid water control during diamond drilling isn’t an extra—it’s just good planning.

Whether it’s for new-build housing cores, industrial installations, or shopping centre fit-outs, keeping water flow contained helps protect everything around the work area. Water leaks cost time, bring stress, and usually mean double work.

The better option is to get it right from the beginning. Working with a crew that understands water behaviour, has the right gear, and knows what to expect makes the job quicker, smoother, and safer. Good gear and a good plan are always worth it when the site is tight and the timeline short.

Manage water leakage from the start to ensure your drilling project in Mansfield remains on schedule. Core-ECT Diamond Drilling offers expert solutions to keep your site efficient, minimise disruptions, and safeguard the workspace. Trust our experienced team to handle diamond drilling with precision and care, helping you navigate complex conditions with ease.